Introduction to Type of Mirrors

- Среда, 01.12.2021, 8:55

- Советы

- Нет комментариев

Type of Mirrors:

Metal Coated mirrors-

The normal mirrors we use in our daily lifestyle are usually silver mirrors on glass. There is a glass plate with a silver coating on the back. The thickness of the coating is enough to suppress the transmission from any side. Since a small of light gets absorbed by the silver layer, therefore it never happens that 100% of the light gets reflected back.

Household mirrors usually have a coating on the back, so that one can have a sturdy glass surface that can be cleaned easily, and the back coating (with an additional layer) is well protected. And for other applications in which the first surface mirror is used where the light directly falls on the coating and does not reach the mirror substrate.

Highly advanced types of metal-coated mirrors have been designed in order to use in laser technology and general optics. These often have additional dielectric layers on top of the metal coating to improve reflectivity and/or protect the metal coating against oxidation (enhanced and protected mirrors). There is a wide range of metals that can be used such as silver, copper, nickel/chrome alloys, gold, aluminum, and beryllium.

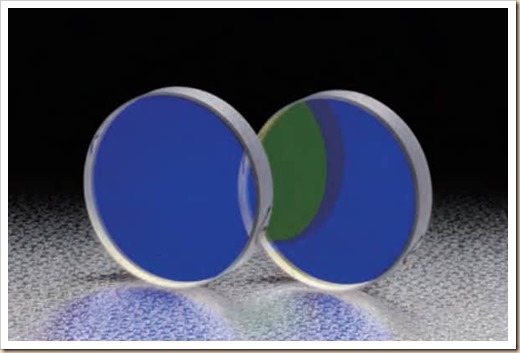

Dielectric mirrors-

A dielectric mirror is the most important type of mirror in laser technology and general optics. This type of material basically has multiple thin dielectric layers. One means the combined effect of reflections at the interfaces between the different layers.

The most commonly used design is that of the Bragg mirror (quarter-wave mirror), which is the simplest design and leads to the highest reflectance at a particular wavelength (the Bragg wavelength). Huge variety of optical mirrors and long wave pass dichroic beam splitters are used for optic polarization.

In comparison to metal-coated mirrors, dielectric mirrors are constructed as first surface mirrors, which means that the front surface of the mirror is the reflecting surface so that the light is not allowed to travel through some transparent substrate before being reflected.

In this way, not only is the potential diffusion loss avoided in the transparent medium but most importantly additional reflections on the front surface, which may be particularly relevant for non-normal phenomena.

In general, the reflection bandwidth of the dielectric mirror is limited. However, there are some broadband dielectric mirrors that are specially adapted, where the reflection bandwidth can be hundreds of nanometers.

Some of them are used in ultrafast laser and amplifier systems; they are sometimes called ultrafast mirrors, and they also need to be optimized in terms of chromatic dispersion.